Le macchine per srotolare l'acciaio sono di grande aiuto nelle industrie poiché contribuiscono a rendere il lavoro più facile e veloce. Immagina di provare a sollevare una pesante bobina d'acciaio da solo - sarebbe davvero difficile! Ma con una taglio di bobine in acciaio , la macchina può occuparsi gran parte del sollevamento pesante al posto tuo. Questo lascia ai lavoratori la possibilità di svolgere altri importanti compiti all'interno della fabbrica.

Gli svolgitori di acciaio afferrano una grossa bobina di acciaio e la distribuiscono lentamente. Questo aiuta gli operai a utilizzare l'acciaio per altri scopi – come tagliarlo in pezzi più piccoli o plasmarlo. Le grandi bobine di acciaio possono essere quasi impossibili da gestire senza un svolgitore. stampi per stampaggio in acciaio .

I vantaggi dell'uso di snocciolatori d'acciaio. Un grande vantaggio è che risparmiano tempo e l'energia associata ai lavoratori. Non è più necessario che i lavoratori si stanchino a trascinare bobine pesanti, basta lasciare che lo snocciolatore d'acciaio faccia tutto il lavoro. Di conseguenza, ne completano di più a un ritmo più veloce, ed è fantastico per la fabbrica.

Gli snocciolatori d'acciaio rendono il compito di manovrare l'acciaio in bobina più rapido e facile. Invece di srotolare una bobina a mano, i lavoratori possono smontarla con l'aiuto di uno snocciolatore d'acciaio. Questo risparmia molto tempo ed energia e permette alle persone di concentrarsi su altri compiti importanti. Alla fine della giornata, gli snocciolatori d'acciaio rendono il maneggio delle bobine d'acciaio più facile ed efficiente.

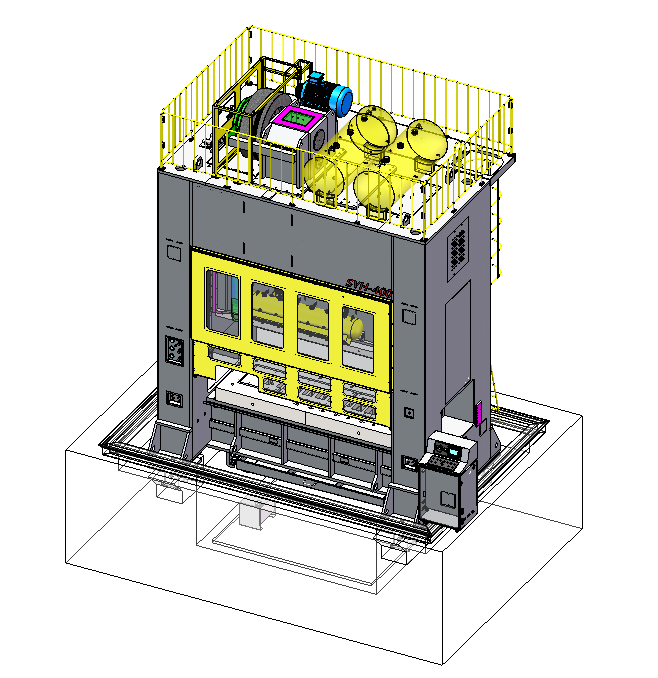

Gli snocciolatori d'acciaio esistono in molti stili in base al lavoro da svolgere. Alcuni sono piccoli e possono accogliere bobine leggere; altri sono grandi e possono gestire bobine pesanti. Il tipo di snocciolatore d'acciaio dipende dal lavoro svolto nella fabbrica. Per esempio, una fabbrica con bobine pesanti richiederà uno snocciolatore d'acciaio grande e robusto.