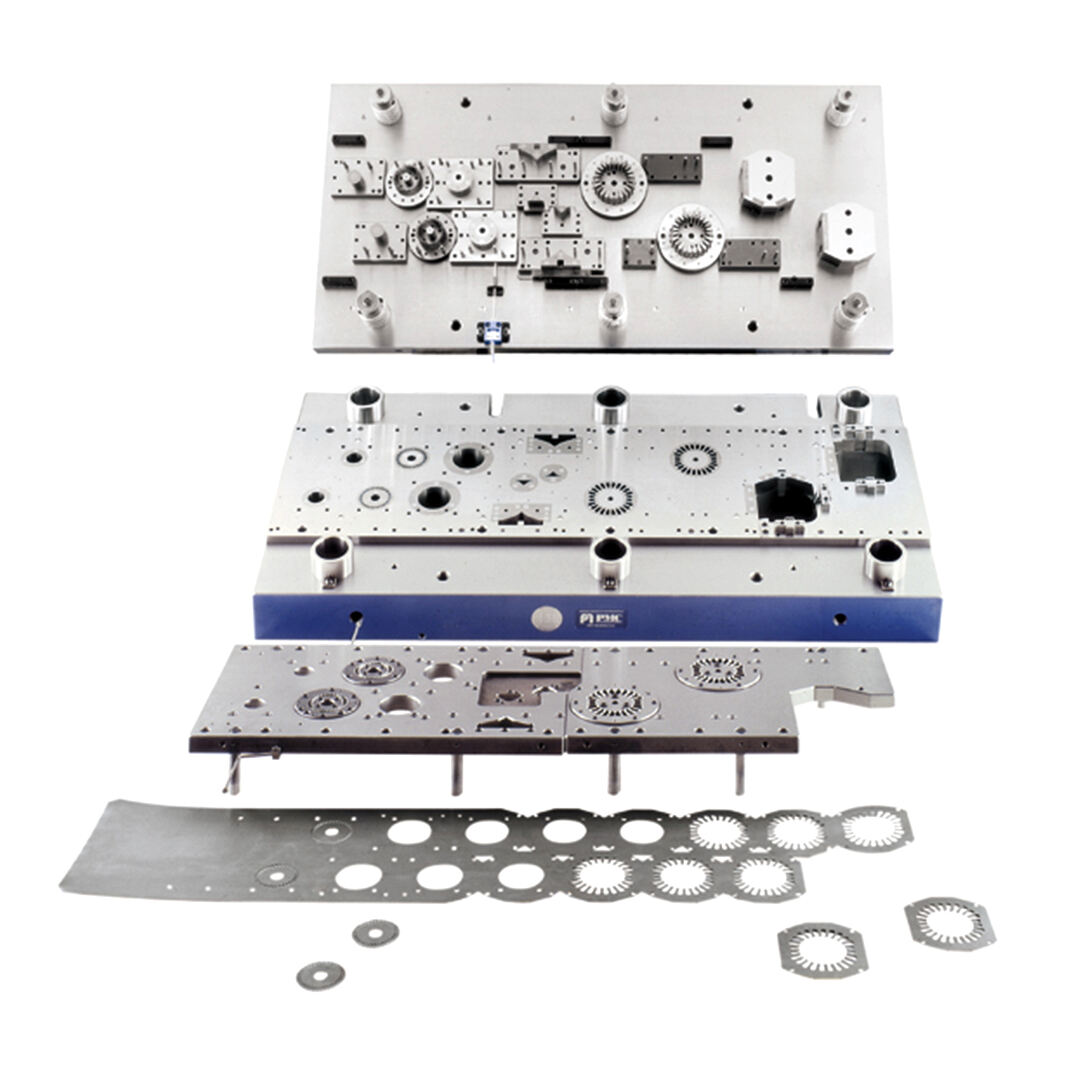

The heavy-duty progressive die stamping from Lihao is one of the key tools for transforming metal sheets into a variety of shapes and sizes. A die is a specialized tool that this machine uses to stamp workpieces from the metal sheets. Die: is a special tool that is made out of super strong steel to cut and shape the metal sheets in an accurate fashion. It makes sure not a single piece is created incorrectly.

The best benefit of the die stamping machine is to make accurate and perfect cuts and shapes at a faster rate. It allows serial production of a large number of the same parts in a short time. It is able to fabricate process the metal sheets into identical pieces so that all of them look alike and assemble seamlessly. It's simply not possible to do this level of speed and accuracy manually. As a result, the die stamping machine core serves to manufacture diverse products in factories.

The manufacturing process is made simple by using a die stamping machine. It minimises the number of workers that need to do this type of work by hand, and as a result, errors can be avoided. Because people are doing this by hand, errors are more prone to occur, but with the machine, mistakes are limited. The die stamping machine may also be programmed to operate for extended periods of time with little or no human support. This allows it to continue operating independently to manufacture greater product output within a shorter timeframe. This enables money savings for big agencies and makes their product speedier that is excellent at some point in the commercial enterprise.

The other beneficial thing about die stamping machines is they are capable of creating custom designs on metal sheets. That is, the machine allows for cutting out different shapes, logos and names from below so that companies can create their own products in a way that bring uniqueness to them by making it stand out and be visible among others. With tight deadlines to meet, quick and efficient creation of custom designs is priority. Using die stamping machine encourages manufacturers to be highly creative and develop unique products.

Die stamping machines are worth their weight (which is a lot) in gold to the car and airplane industries. They are used to manufacture many of the parts that go into making cars and planes, including engine parts, body panels and other vital elements. For these industries, the die stamping machine's capability to quickly make mass production of similar pieces is extremely advantageous. This will enable manufacturers to meet the increased demand for components required for vehicle and aircraft assembly.

Lihao Machine provides tailored solutions also a complete site meet various needs of clients. With a wide assortment of, including three-in feeders-one Cum Straightener machines, NC servo feeders, plus punch machines, we offer comprehensive service for manufacturing, design and sales, also service plus trading. Our R&committed D team personalized options and technical discussions, guaranteeing each solution is completely designed to fulfill your preferences.

With over 26 years of leading place, Lihao Machine is the top supplier the domestic and international markets. Our products are utilized in a wide array of approximately the entire world. You can expect our clients worldwide with over 20 offices across China while the branch in India. We provide customized options in a lot of industries many thanks our substantial technological capabilities.

We excel in engineering plus robust tooling designs that minimize adjustments to your setup and for that reason reducing production that is scrap. Our die stamping machine offer global commissioning and training, ensuring integration that is seamless maximum performance for the realm. With in-house manufacturing plus quality parts which can be spare we guarantee minimal downtime along with maximum efficiency. Accredited with ISO9001:2000 plus EU CE we stay glued to the best standards of quality.

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.