When you are working with metal and we mean you are MAKING something WITH metal it is really important to be ACCURATE. A metal stamping press is a uniquely designed machine that can aid in this. In factories, it performs like a superhero. It is a machine to make things fast and precise. So, how does a metal stamping press machine work for companies like Lihao to produce various metal products?

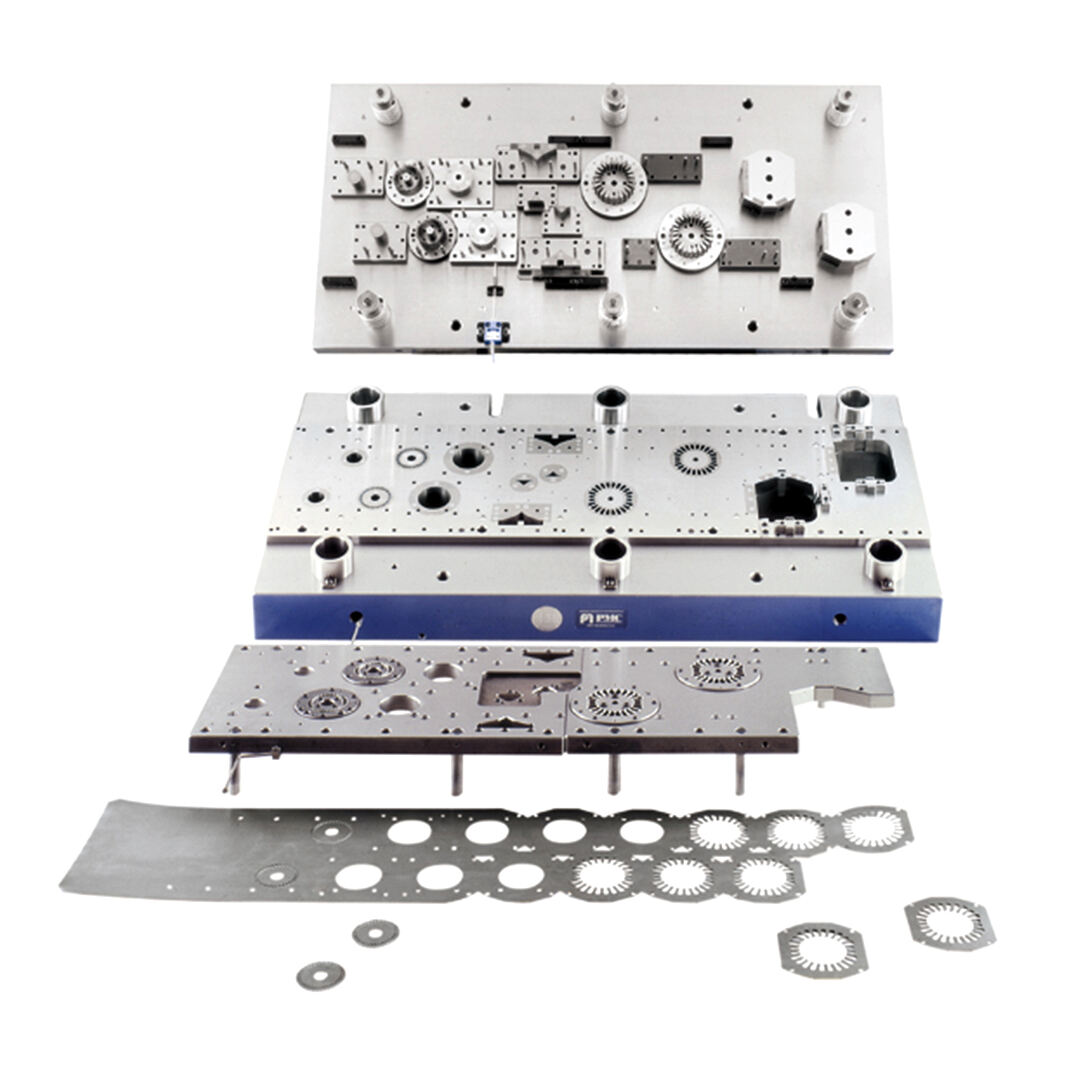

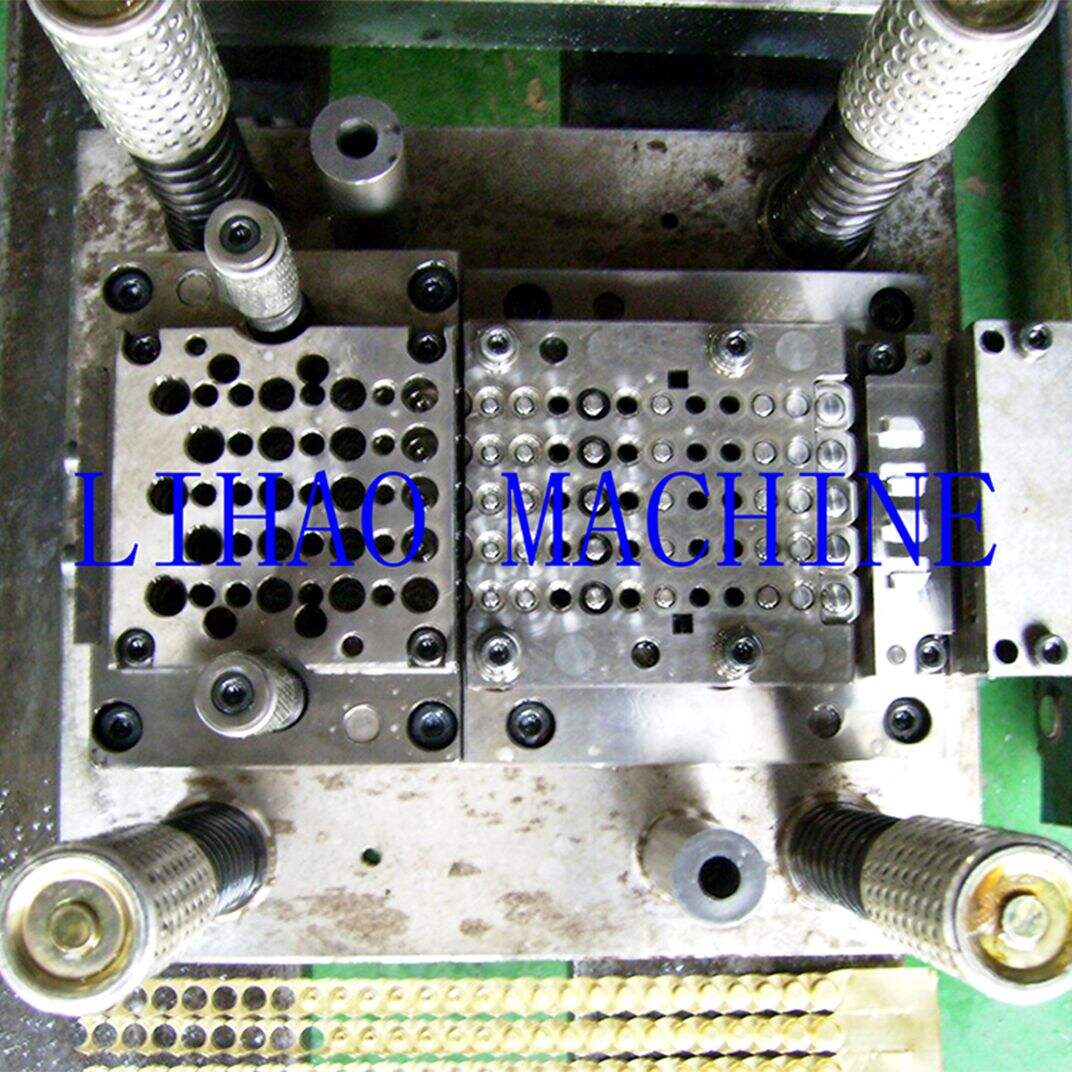

You have this big piece of metal and you want to make many smaller pieces. A metal stamping press machine is essentially a giant cookie cutter that can punch those pieces out quickly and accurately. It uses a tool, known as a die, to smash shapes into the metal at the perfect level of force. Then every piece looks exactly the same every time, no errors. This precision is critical so that all of the pieces can fit together properly in the end product.

A metal stamping press machine is what Lihao and others use in order to get their production line running more efficiently. These automatic machines can work nonstop, and quickly make parts. That way companies could get products to market faster, meet deadlines and stay up to date on what customers want. This saves time and money.

Metal stamping press machines can be incredibly useful and very useful for a variety of manufacturing needs. Whether you’re trying to manufacture small parts for electronics or larger parts for appliances, a metal stamping press can make it happen. These machines can handle various metals, such as steel, aluminum and copper, so manufacturers can produce a variety of products. It's this versatility that makes metal stamping press machines so vital to any manufacturing firm.

Modern technology has led to advancements that make metal stamping press machines better, faster and cheaper. In modern machines, computerized controls enable the machine to make fine adjustments. This makes products better and minimizes waste.” And production can move faster with things like robotic arms and conveyor belts. Companies stay ahead with the latest technology and can produce more.

Metal stamping press machines are capable of much more than simply cutting and shaping metal parts. They are also capable of bending, forming and adding designs, which extends a wide range of opportunities for manufacturers. They can form complex shapes that would be difficult to make by hand. Able to produce a large amount of parts in a short period of time, metal stamping press machines are vital for companies poised for growth.