An Extensive Book on Pneumatic Presses for Manufacturing Industries And Illustration Usage

Industrial Importance Of Pneumatic PressesBecause they provide the right amount of force or compression and also a large reliable power source. This class of machines works by using air pressure to push a piston or cylinder (or alternatively) that in turn pushes the material through a die or mold. Pneumatic presses come in various types, designs and sizes to suit the requirements of a wide range of manufacturers.

The 10 Best Industrial Pneumatic Presses (Reviewed)

1. Ingersoll Rand 7803RA Heavy-Duty Barrel Air Hammer. This pneumatic press is widely known for its powerful motor and adjustable speed trigger. It is particularly suitable for heavy industrial applications, as it can deliver up to 3500 blows per minute on several barrel sizes. Baileigh HSP-30A Air/Hand operated H-frame press. This press is made of high-quality materials and can offer up to 30 tons of force. Since it has an adjustable table height, this press is excellent for hard jobs. 3. Dake B-10 Model Manual Utility Hydraulic Bench Press. This bench press is efficient and offers fast and reliable results on a wide array of materials. 4. Dayton 12T955 Arbor Air Press. The press is intended for hard usage since it has a powerful 2HP motor that can deliver up to 7500 lbs of force. Its stroke can be adjusted. 5. Edwards HAT5010 50 Ton Shop Press. This press is made for enduring heavy work. WIth 50 tons of force, a welded frame, and cast iron bed, with adjustable table, it is instrumental. 6. IDP-15T 15 Ton Hydraulic H-Frame Press. This machine can offer up to 15 tons of force on a variety of materials since it has an adjustable table. 7. JET AP-5 5 Ton Arbor Press. Jet press is strong due to its hardened frame. Its precision is suitable for meticulous work, since it is made to apply 5 tons of force. 8. Milwaukee 49-16-2696 M18 FUEL 1-3/4 in. 15° Coil Roofing Nailer. Milwaukee press is particularly useful in tough workplaces, as it can reach 120 psi, but is light and cordless. 9. Pro-Tools MB-105HD Hydraulic Tube Bender. This press was designed to make bending metal tubes accessible due to its manual control valve and control arms. 10. Wabash MPI Pneumatic Presses. Wabash machines come in packs, and all present a formidable force, sometimes up to 250 tons. They excel in presenting numerous pressing options which perform with acceptable precision and reliability across materials.

Types of Pneumatic Press Available for Various Industrial Activities

There are several important factors that need to be considered when selecting a pneumatic press for industrial use. Some of the key factors are material properties, and production volume... Although there is a long list but let us start by these points then gradually will understand other ones like force capacity, type of die or mold etc.

Materials that require force or compression can be used with pneumatic presses like plastics, composites and metals. Material thickness, hardness and ductility are some of the factors that will influence your choice for pneumatic press.

Force Capacity Requirement:

Pneumatic presses are capable of a few tons to several hundred tons force capacities. Some materials need more force or larger die sizes, making higher-force capacity presses required.

Die or Mold Type:

Stamping, forming, cutting etc. are different processes that require specific dies and molds to be able to perform these tasks with optimum results. Various die types can be used on pneumatic presses including C-frame, H-frame and arbor version.

Volume Of Production:

The Pneumatic presses should be selected in accordance with the volume of production. Larger presses, requiring larger dies per press (which may have to be done manually); an order of magnitude whose production volume can mean the difference between spending a few hours per week changing over with smaller machines vs!

Pneumatic VS Hydraulic Presses in Industrial Applications

Pneumatic and hydraulic presses are used in the industrial process, with their own pros and cons. Pneumatic presses are often lower in cost, simpler to maintain and more transportable than their hydraulic counterparts. They are very good at providing accurate and repeatable results, but they have low force capacity, need compressed air and can produce high noise levels.

In contrast, hydraulic presses provide greater force capacity and are faster than screw type models so they work well with heavier duty applications. They are more energy-efficient and less maintenance, they cost a bit more to buy; however require oil/hydraulic fluid compared single-phase wiring is used with an air pressure assist., They have slower cycle times when compare pneumatic presses

Understanding How a Pneumatic Press Can Be So Useful when Manufacturing

Instead, it's a low-cost substitute for hydraulic presses.

Mobility of variation

Perfection / Uniformity of Operations

Minimal noise output

Common Pneumatic Press Issues & Troubleshooting Techniques

Regarding the Pneumatic Presses, since it is a machine like every other one out there,There may be some operating difficulties affecting its functioning. Common issues & solutions

Air Leaks - Inspect hoses and fittings for damage or loose connections, tighten or replace parts and check press.

Pressure Inconsistency: Adjust the air compressor output, volume regulator valve or speed control valve so that pressure is consistent.

Slow cycle time possible causes: Low air pressure, Air leaks, Worn seals or bearings and inadequate lubrication. REPAIR: Inspect these components to see if they either need replacing or lubricating.

In summary, based on the properties of materials being used to stamp a piece and also amount pressure required from it for industrial purposes could be totally different so selecting pneumatic press can only conclude after evaluating material characteristics, force requirements capacity type solid metal die cut or Ruby Die Cut, production volume and cost. There are both pros and cons of pneumatic vs hydraulic presses which can be best understood by knowing the specifics.

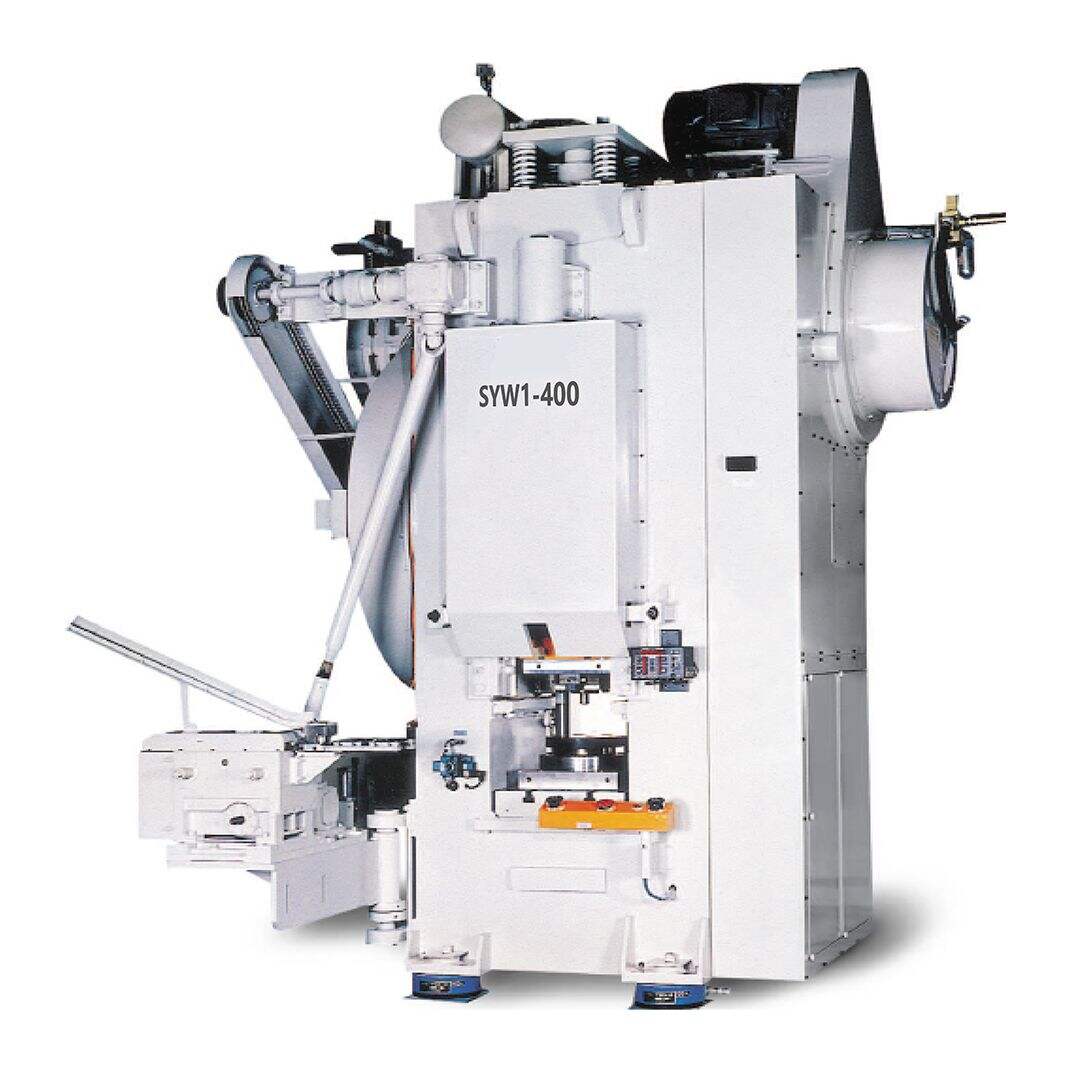

We are specialists in the world of engineering and durable tooling designs, while minimizing setup adjustments and scrap production that is reducing. Our pneumatic press offer global commissioning and training that ensures integration that is seamless performance worldwide which is optimum. We be sure efficiency that is maximum minimized downtime with your in-house production, quality free parts and support this is certainly technical. Since a ISO9001:2000 that is certified and EU CE, we uphold the product quality standards which is finest.

With over 26 years of leading place, Lihao Machine is the top supplier the domestic and international markets. Our products are utilized in a wide array of approximately the entire world. You can expect our clients worldwide with over 20 offices across China while the branch in India. We provide customized options in a lot of industries many thanks our substantial technological capabilities.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.

Lihao Machine provides tailored solutions also as a complete service meet up with the various needs of customers. You can expect integrated solutions which cover design, production and sales. Our R&committed D team provide you with customized choices and technical discussions making sure each option would be suited to your unique criteria.