Progressive die tooling is about making things in a factory. It makes metal parts, and other things, we use every day. Lihao is a manufacturer of progressive die, and they are quite good. Let’s take a closer look at what progressive die tooling is and why it's so important.

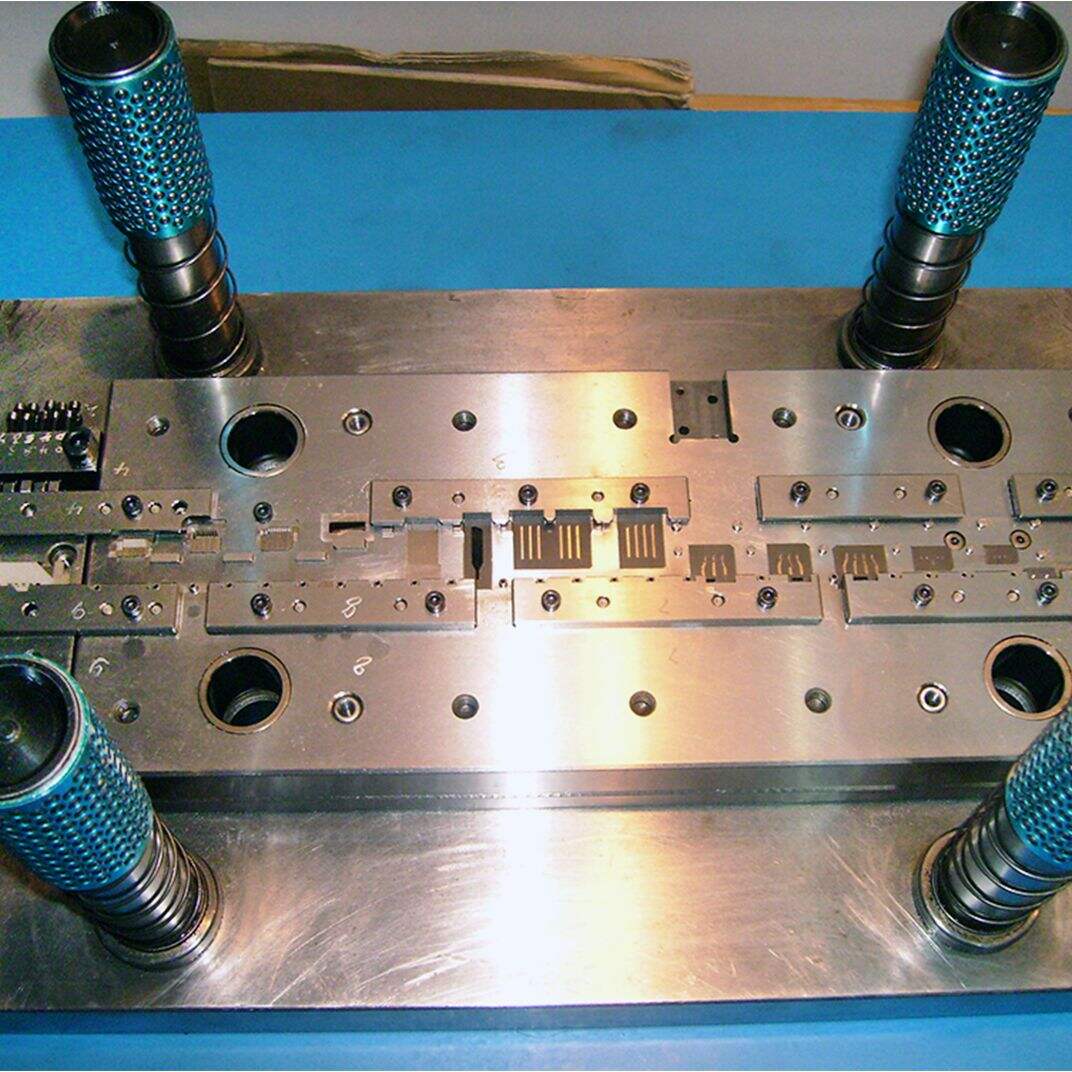

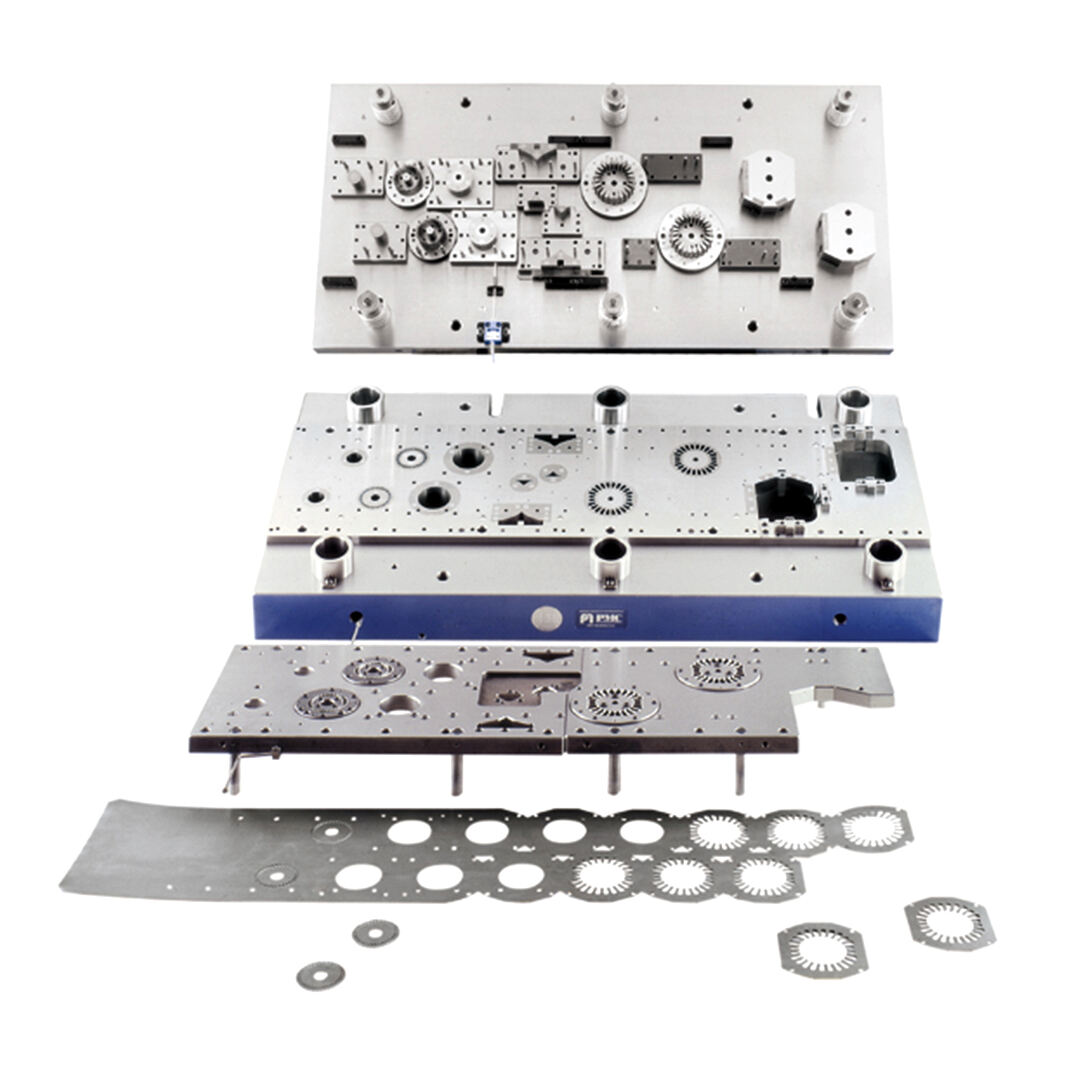

Progressive Die Tooling – A Special Tool to Make Things In a Factory. It can make a lot of things at the same time, which is time- and cost-saving. With the die tooling, workers can turn out plenty of parts quickly and accurately. This is crucial, as it means that factories can churn out more in less time.

Progressive die tooling is a little like a magic machine that exists to make things faster and easier. It takes metal parts and cuts and shapes them to the right forms. It makes the production flow nice and rapid. A factory that uses stamping die can produce a lot of parts very quickly. This helps the factory understand what customers want and make sure they have plenty of products to sell.

The use of progressive die tooling is a good way to do it. A progressive die tool allows workers to produce many parts at once rather than individually forging each part. This saves time and money since workers could produce additional parts in less time. This also allows factories to make more things and sell them more quickly. Fontana agrees utilizing progressive die tooling factories can work more efficiently and compete more effectively in the marketplace.

It is an important part in manufacturing process. It makes it easier for factories to produce things fast and right. Without progressive die tooling, a plant would otherwise need to manufacture each part by hand, and the process would be a time-consuming one. It would make it difficult for factories to fulfill customer orders and could mean delays in producing goods. By using progressive die tooling, factories can make many parts at once, which helps them keep up with the schedule and demands of their customers.

For_proto_Progressive die tooling includes special technology to make certain every part is formed correctly. It has been used to cut and shape metal parts with high precision. This means that the components produced by a progressive die are the correct size and shape, every time. This is significant as this will save the risk of errors in terms of production. Through the use of progressive die tooling technology, factories can deliver quality objects that the customer expects.

Lihao machine has been a leader on the market since 1996. It had been a reliable supplier regarding the national and international markets. Our items are used throughout the selection of industries around the world. We offer our clients worldwide with more than 20 offices in China additionally the branch in India. Our robust technological capabilities enable customized solutions for a variety of industries.

Lihao Machine offers tailored solutions and complete services to fulfill different customer. We offering integrated services that encompass design, manufacturing and sales. Our committed R&D team will provide your with personalized alternatives and technical discussion guaranteeing each solution is perfectly customized to satisfy your own needs.

We are specialists into the design and development of strong tooling, that can help to reduce setup adjustments as well as reduces scrap production. Our progressive die tooling offer global training and commissioning, ensuring performance that is maximum integration worldwide this is certainly seamless. In-house manufacturing and top-quality spare parts provider we could guarantee downtime which is maximum productivity that is minimum. Certified and ISO9001:2000 and EU CE We uphold the standards that are standard are greatest.

Our dedication to reliability, innovation and continuous enhancement of products and services is a consistent. Our highly Lihao ensures cutting-edge solutions that produce us the top choice for equipment for stamping automation. We place a high priority in ensuring customer satisfaction by consistently providing the quality solutions being highest and services.