It is not a simple task to make car parts. So each (part) has its own shape, its own size and are all very complex parts that get made very, very carefully. That's why companies like Lihao have specialized in automotive stamping diess which make the manufacturing of the car parts easy. So, in this text, we will get to know what are automotive stamping machines, how they work, and why they are important to make cars faster and better.

Speed is of the essence when manufacturing car parts. They need to be able to make parts as fast as they possibly can, and at the same time, ensure those parts are high quality. This is where automotive stamping machines come into the picture. “These machines operate in a punching and stamping way to create car parts from large sheets of metal. It is similar to cutting cookies with a cookie cutter—the stamping machine slices a shape from a mass. It slices shapes out of large pieces of metal, the way you cut cookies out of a slab of rolled-out dough.

Automotive stamping machines are very accurate and one of the biggest advantages of it. Each car component needs to fall into place precisely, particularly the components that protect us while driving. Like the seatbelts, and the frame of the car, they have to mesh perfectly. A stamping machine can cut parts with amazing accuracy, within one thousandth of an inch. That’s tinier than a grain of sand!” This level of accuracy means that most of the time, there is no need for extra work on the parts to fix anything, which can save time and money during the manufacturing process as a whole.

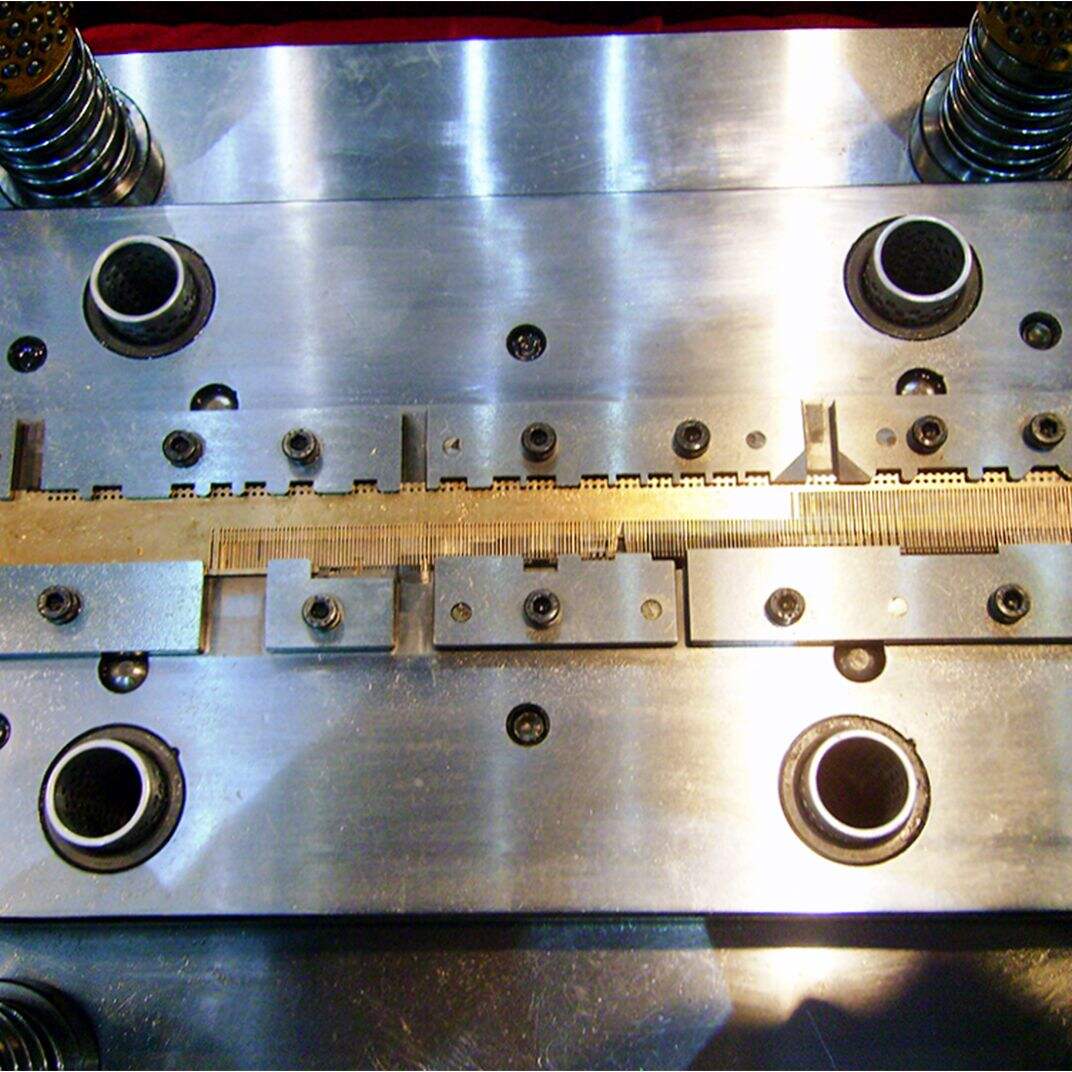

Stamping machines used in automotive manufacturing are able to produce many different types of components. They can produce small components like brackets — which help keep things in position — and larger parts, like hoods, which cover the engine. Its operation is quite simple and efficient — the machine takes a metal sheet and inserts it into a stamping area. Then, it punches out the required part shape. Then there are several processes a machine undertakes to ensure a part is fit for use.move It needs to be shaped properly, bent into the correct position, and sometimes plated with a special substance to prevent it from corroding. These steps are all designed to make sure a part is up to snuff with regards to safety and quality.

Automotive stamping machines have evolved quite a bit in how car parts are manufactured. Historically, the process to manufacture car parts was a laborious and difficult one requiring time and man-hours. Errors could creep in easily because everything was done manually. But now, aided by stamping machines, parts can be formed quickly and with few mistakes. This change has drastically improved the car manufacturing process, from the very first design stage to the final car production.

Moments like these are a major part of how automobiles are made all the way up today, automotive stamping machines. They are crucial in making sure that car parts are made right, fast, and cheap. This is because it is important for the auto makers and general public to have cars safe and reliable. Stamping machines enable car manufacturers to adhere to new technologies and innovations that ensure their companies continue to grow and thrive in a competitive world.

Our dedication to reliability, innovation and continuous enhancement of products and services is a consistent. Our highly Lihao ensures cutting-edge solutions that produce us the top choice for equipment for stamping automation. We place a high priority in ensuring customer satisfaction by consistently providing the quality solutions being highest and services.

Lihao Machine happens to be a leader looking for over 26 years. This might be a reliable supplier on the area and international markets. Our items can be used by way of a number of industries around the world. Our customers are worldwide with more than 20 offices in China as well as an indian branch. Our robust technological capabilities enable customized solutions for the variety of industries.

Lihao Machine provides tailored solutions also a complete site meet various needs of clients. With a wide assortment of, including three-in feeders-one Cum Straightener machines, NC servo feeders, plus punch machines, we offer comprehensive service for manufacturing, design and sales, also service plus trading. Our R&committed D team personalized options and technical discussions, guaranteeing each solution is completely designed to fulfill your preferences.

Our company is experts in the development and design of durable tooling that can help to attenuate setup adjustments too as reduces scrap production. Our automotive stamping machine offering training that is worldwide commissioning, which ensures the performance which is highest and seamless integration around the world. With your very manufacturing that is own and high-quality spare parts service we guarantee minimal interruptions in addition to productivity that is highest. We are ISO9001:2000 accredited and EU CE certified.