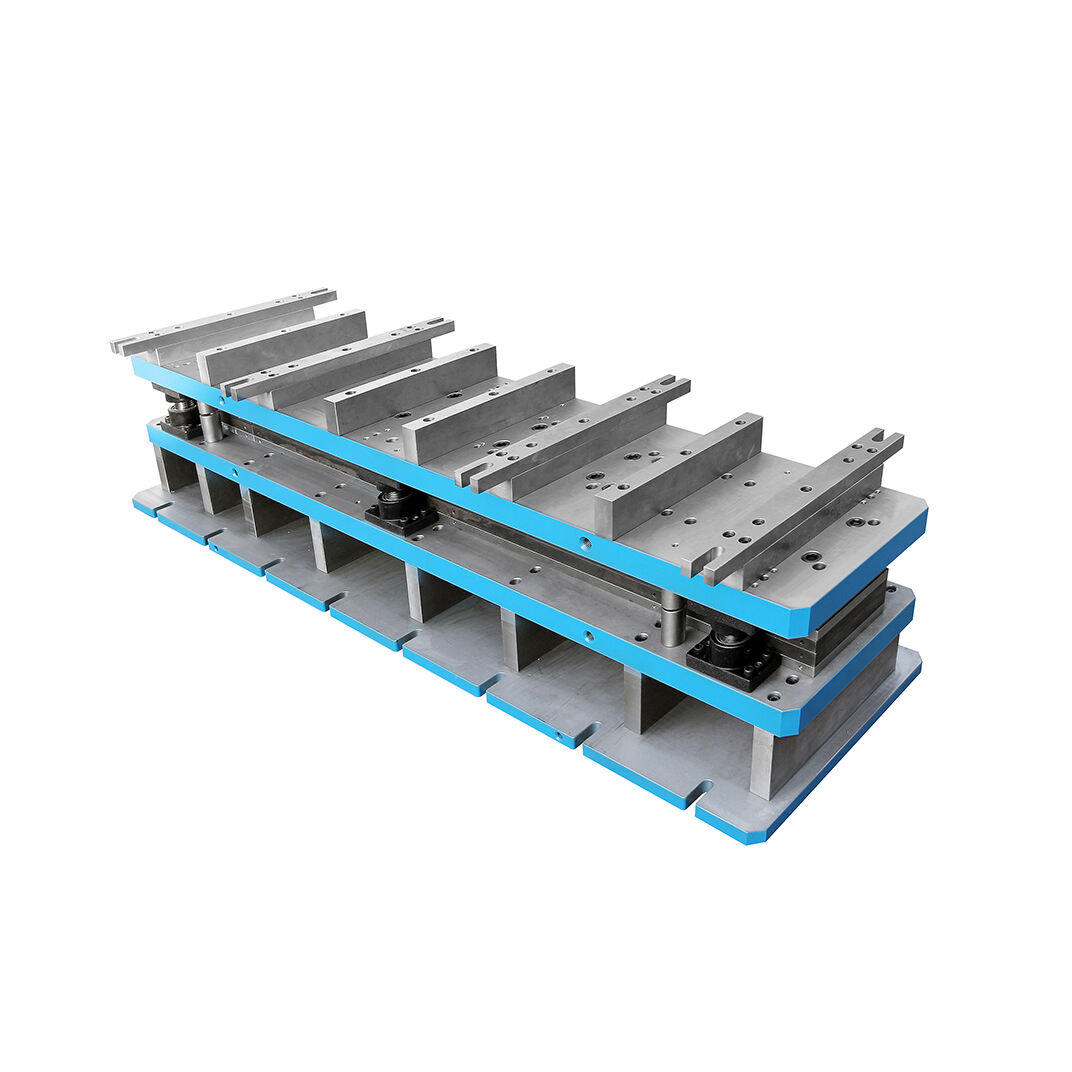

A major profession, metal work allows a range of different types of metal products that are used in our everyday activities. Work of this nature involves the manipulation and formation of metal by various means. A sheet metal die is one of the most important tools used in this process. This unique tool is designed to cut metal sheets into various shapes and patterns. A New Age of Sheet Metal Die Although not that new, an exciting sheet metal die type has come about recently. This is referred to as a progressive sheet metal die.

Progressive sheet metal dies are unique in that they can be used to cut and bend a particular shape from a metal sheet, all at one time. So workers can produce multiple forms and designs in a short period. This is pretty useful when a large volume of metal items needs to be produced simultaneously. Progressive dies help to expedite work for manufacturers, making the process both quicker and cheaper, which in turn allows them to meet their consumers needs.

Craftsmanship for February 2020 Technology has greatly the metal work. Progressive sheet metal dies allow workers to make more intricate and complex designs than select ever before. This allows manufacturers to create not only aesthetically pleasing but also extremely reliable metal parts. The standardization from progressive dies leads to a much higher level of accuracy and repeatability seen in each final product — they are all made at the same quality.

Within the metal work sector, there are quality + speed standards that everyone wants. These standards are crucial in making certain customers receive quality goods. These standards have improved drastically with the evolution of the progressive sheet metal dies. These unique dies ensure that the employees are able to provide metal goods, which have an improved level of precision and uniformity, thereby improving the entire quality of the output that is being achieved.

Creating metal products can be time-consuming and expensive. On the flip side, progressive sheet metal dies have made several advantages to the part metal working process. By enabling a worker to manufacture several products in less time, they assist in conserving both money and time. The precision of these dies means that the work done need fewer workers to correct errors, thus improving the quality of metal products greatly.

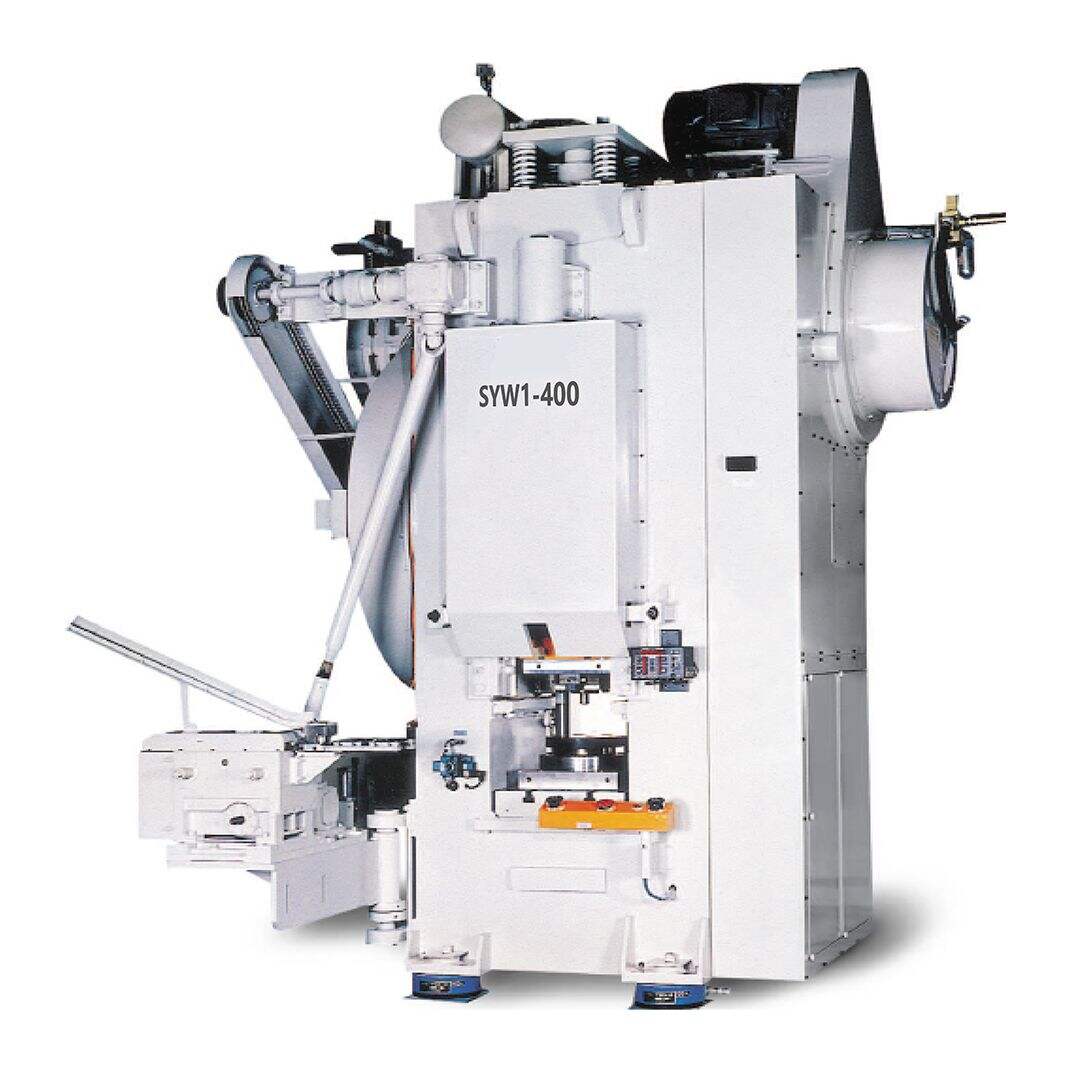

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

Lihao Machine provides tailored solutions as well as a complete service meet with the varied needs of your customers. With a wide quantity of things like three-in-one feeders Decoiler Cum Straightener machines, NC servo feeders, and punch machines, we provide integrated services covering design production, provider and trading. Our R&dedicated D team customized options plus technical discussions making sure each solution is suitable to your unique requirements.

We are specialists in engineering and robust design of tools, which helps in reducing set-up adjustments and scrap production that is reducing. Our progressive sheet metal dies offer worldwide training and commissioning to make sure performance this is certainly optimal seamless integration across the planet. We guarantee maximum efficiency plus minimized downtime by providing in-house production, high-quality spare parts, and support which is ongoing. As a ISO9001:2000 that is certified and EU CE We uphold the best standards of quality.

Our dedication to quality, reliability and continual improvement of our services plus products is an ongoing procedure. Our Lihao team is highly trained and certainly will provide cutting-edge solutions. Our company is the true number one option for stamping automation. We place a high benefits customer satisfaction, offering top-quality products and superior services consistently.