Stamping mould are special devices utilized to form shapes or designs on materials, which are mostly metal and plastic. These molds are similar to stamps which press the material down to make an impact. Stamping moulds have to be thought out very carefully to guarantee they can work properly. Learn about stamping moulds and how they are manufactured.

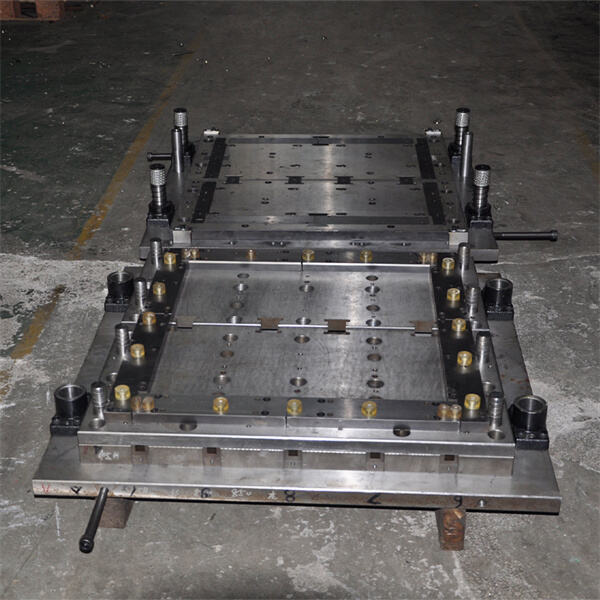

Mold design is the design of the mould we need. The size and shape as well as the details of Lihao's engineering are carefully considered. They apply special computer programs to generate a digital blueprint of the mould before producing it. This is a way to make sure that everything fits together just perfectly for them.

Selecting the appropriate materials for a stamping mold are very important. The paper has to be able to take the punches. At Lihao, engineers typically use hard-and-tough metals, such as steel, for the factory’s stamping moulds. Steel is durable and can be recycled for use in many products.

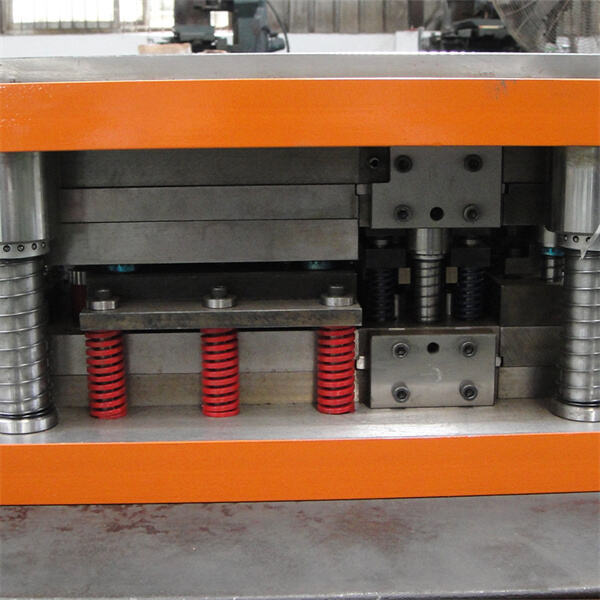

When it comes to progressive stamping mould manufacture, precision is everything. If the mould is to function properly everything must be just right. Attention to detail is important to Lihao's engineers, who make all screw holes line up and places things where they should go. In the stamping process, the slightest error can bring things to a grinding halt, so accuracy is of the utmost importance.

In order to produce stamping die moulds more efficiently, employs special machines and tools to expedite the process. They also have trained workers who are accustomed to working accurately, fast. With an efficient production process, it can make great stamping moulds at less time driving up efficiency and cutting costs.

The metal stamping dies mould technology is based on continuous investment in the latest technologies. They utilize latest software and tools to fabricate accurate stamping dies. Being aware of all of the most recent technological advancements means to be able to provide their customers with the finest of products.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our Stamping mould offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

Lihao Machine happens to be the marketplace leader for 26 ages. It's the trusted provider both domestic and international markets. Our items are extensively utilized in many industries throughout the world. We offer our customers throughout the global world with nearly 20 offices in China and an indian branch. We offer tailored systems around many industries using our advanced technological capabilities.

Lihao Machine offers tailored solutions along with a wide range of services to fulfill various customer. With a broad variety of merchandise, including 3 within one feeders, Decoiler Cum Straightener machines, NC servo feeders, and punch machines, you can expect integrated service covering manufacturing design, sales, service, and trading. Our R&D team is dedicated to ensuring customization and technical discussions, ensuring that each product was designed to hook up together with your unique specifications.

Our dedication to innovation, reliability and constant improvement of services and goods are an ongoing procedure. Our Lihao team is extremely experienced and delivers cutting-edge technology. We are the first selection automation of. We place lots of focus on customer satisfaction by consistently supplying top quality and services.