Did you know that steel stamping dies are crucial devices that help to make things? They mold metal into various shapes that we use daily. Let’s check out steel stamping dies and what they do!

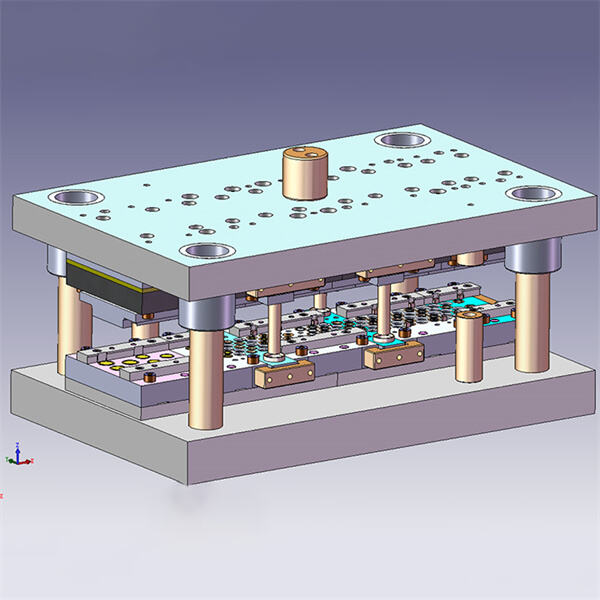

Steel stamping dies are essentially large metal cookie cutters that turn metal sheets into specific shapes. These have two sections, the top section and the bottom section. The part that is shaped at the top is like the top of a cookie cutter, and that which is shaped at the bottom is like the bottom. As the two parts clamp together, they force the metal sheet to go down into the shape we want.

Steel stamping dies are key in the manufacturing of products. They allow you to make things fast and perfect. That’s right — all sorts of things we see every day, from car parts to appliance elements to even toys, are produced with the help of steel stamping dies. Without such tools, manufacturing these products would be far more time-consuming.

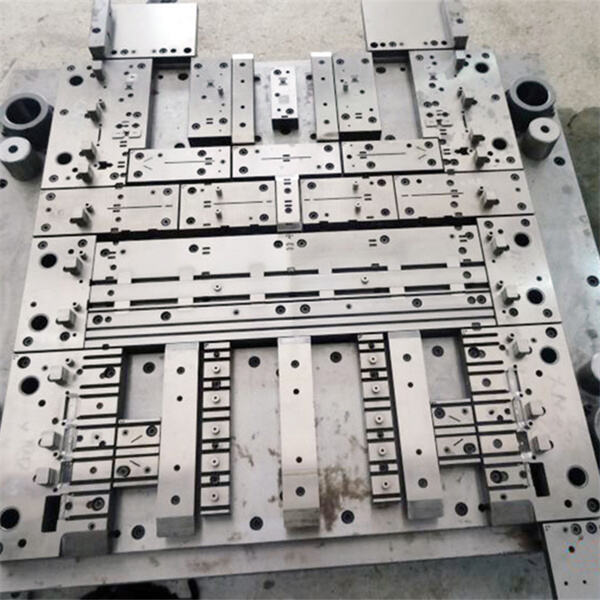

And when considering which steel is best for your stamping die, you have to consider things like strength and how long it will last. At Lihao, we utilise heavy duty steel materials. This is what makes our dies last longer and allow us to create high-quality products.

You’ll want to care for your steel stamping die so it remains in good condition. That way you clean the die out after every use, inspect for damage (and replace if when in doubt), then you have to re-lube the moving parts to decrease friction. You can make your stamping die have a long life span and work well as long as you take good care of it.

From time to time, steel stamping dies experience issues, such as chipping, cracking, or failing to form evenly. If you notice any of these problems, discontinue use of the die and inspect it for damage. Occasionally, however, a few minor repairs can undo the damage. However, if the damage is excessive, then you may need to replace the die.