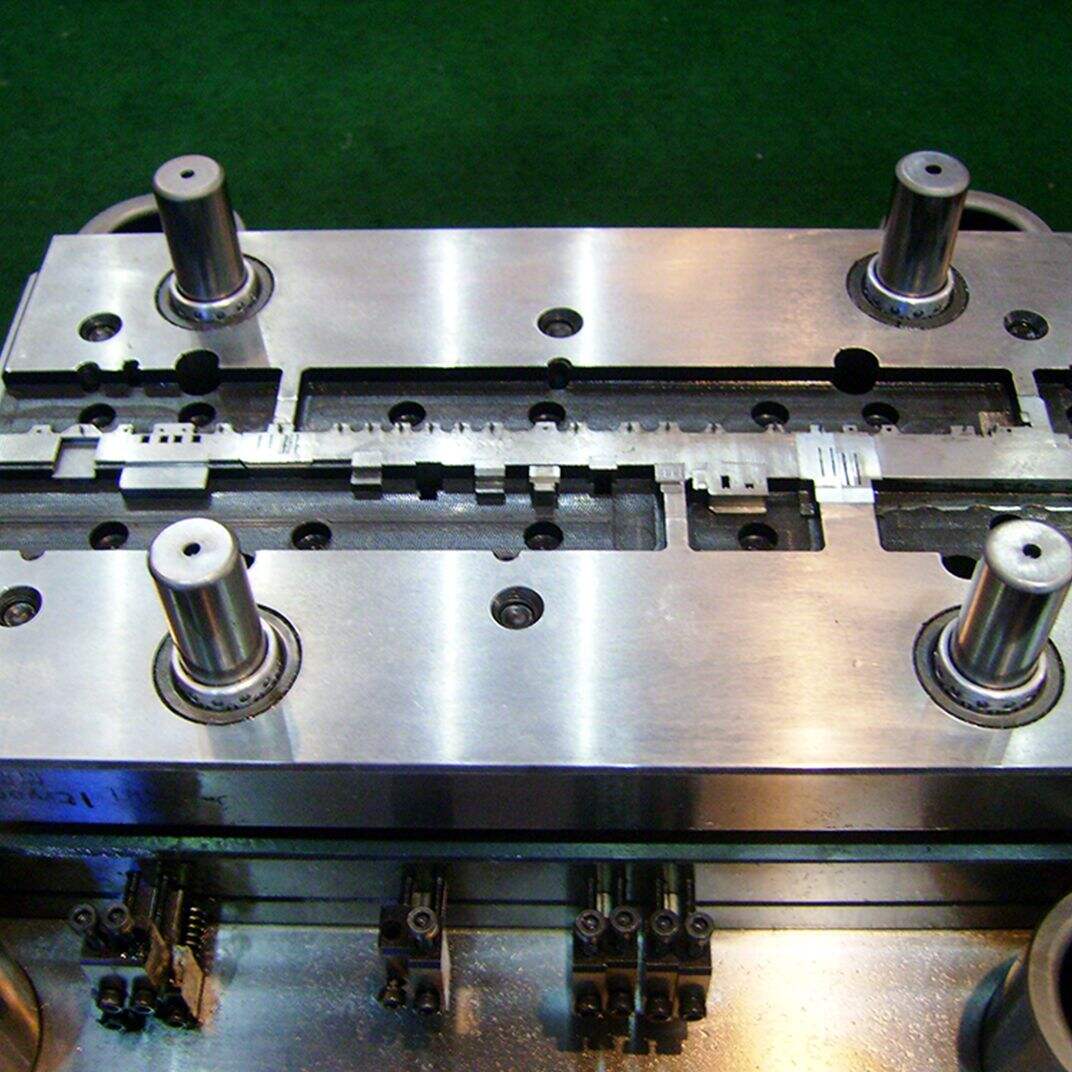

You may recognize these rubber stamps if you ever did arts and crafts. These are fun tools that allow you to create designs on paper. Stamping dies are similar to rubber stamps, but the latter can be as heavy and large. A stamping die is a special tool to help metalworking — the stamping die process of cutting and forming sheet metal, such as by punching or spinning. Usually made of strong and durable steel, it is capable of dealing with the hardest types of work. Producing stamping dies is a highly skilled endeavor, involving engineering and manufacturing expertise of the sort that generally goes into the creation of products.

A quality machine die design is crucial than everything else, and it takes a lot of unique skills. A designer (the person who creates the die) is forced to consider hundreds of elements for this die to work properly. They must take into account, for instance, the type of metal used to make it, what shape and size are required and how the die is produced.

The resulting die also must be considered based on how it will be used after fabrication. Will it be used to prospectively mass produce parts for lots of spares or will only a few part ever be made? Are you making one part in a press, will the machine have a process to make tons of parts fast? These are good questions that should help to influence how the stamping die is designed in a way so that it will operate in the intended manner.

Stamping die designing is not an easy part. The process takes some getting used to because everything is interrelated in the process. This metal stamping dies is where a company like Lihao does its job — it offers greater assistance in the creation of metal parts and have expert professionals who designs everything mentioned above.

Lihao creates complex 3D models of the stamping die using unique computer programs. This steel stamping dies technique is an opportunity for them to try the die and refine it before they go out and put real product. Through standardizing the rather complex process, is able to deliver functional stamping dies of quality that save money for their clients.

Metal fabrication is a very exciting industry to enter, with metal stamping die multiple opportunities for growth in the future. As demand for metal products increases globally, companies such as are utilizing historical processes like continuous casting in very new ways in order to produce higher quality product faster.

Lihao produces innovative designs for stamping dies which are ensuring continued growth of the industry These fantastic items can be found used by lots of organizations to generate all fashion of metal things. This progressive stamping die ranges from cars and electronics to home appliances and industrial equipment. In the manufacturing process of all these products, stamping die designs are used by consumers.

We have been specialists in the design and engineering of durable tooling that minimizes setup adjustments and production that is scrap is reduces. Our Stamping die design are able to deliver training that is global commissioning that ensures seamless integration and optimized performance globally. With in-house manufacturing plus quality parts that are spare we guarantee minimal interruptions plus the productivity this is certainly highest. As a ISO9001:2000 that is certified plus EU CE we abide by the high quality standards being highest.

We are aimed at innovation and dependability and will also be constantly expanding our services and items. Our knowledgeable Lihao team has the capacity to provide cutting-edge solutions, creating us the preferred choice equipment for stamping automation. We have been devoted to customer satisfaction, providing top-quality equipment excellent provider consistently.

Lihao Machine is a huge market for more than 26 years. It really is an established supplier regarding the domestic and international markets. Our products are extensively used in numerous industries for the globe. All around the globe with additional than twenty offices in China and an overseas branch in India we create our clients. Our extensive capabilities are technological customized choices for a variety of industries.

Lihao Machine provides tailored solutions also a complete site meet various needs of clients. With a wide assortment of, including three-in feeders-one Cum Straightener machines, NC servo feeders, plus punch machines, we offer comprehensive service for manufacturing, design and sales, also service plus trading. Our R&committed D team personalized options and technical discussions, guaranteeing each solution is completely designed to fulfill your preferences.