ஸ்டாம்பிங்-ஐ சார்ந்து உற்பத்தி நிறுவனங்களுக்கு, இக்கேள்வி எழும்: இந்த டை-யை இன்னும் எத்தனை முறை பயன்படுத்தலாம்? இது ஒரு மில்லியன் டாலர் கேள்வி போல் இருக்கலாம் (நிச்சயமாக எழுத்துப்பூர்வமாக இல்லை!), ஆனால் நிச்சயம் வித்தியாசம் செய்யும். துரதிர்ஷ்டவசமாக, இதற்கு ஒரு தனித்துவமான, எளிய பதில் இல்லை. ஒரு லைட்பல்பைப் போல் முன்கூட்டியே கணிக்கக்கூடிய ஆயுட்காலம் உலோக ஸ்டாம்பிங் டைக்கு இல்லை. ஒரே ஒரு எண்ணை எதிர்பார்ப்பது நிஜமாகவே சாத்தியமில்லை, ஆனால் எந்த மாறிகளை அடிப்படையாகக் கொண்டு இருக்கிறது என்பதை அறிவது முக்கியம்.

ஒரு மாய எண் இல்லாததற்கான காரணம்:

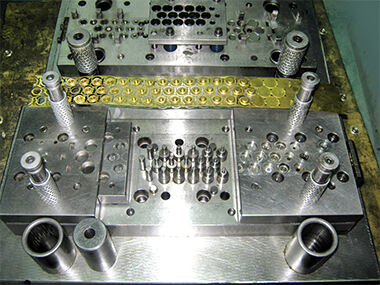

ஒரு டை என்பது உறைந்து போன கருவியாக இல்லாமல், ஸ்டீராய்டுகள் பயன்படுத்தும் விளையாட்டு வீரரைப் போலவும், நிமிடத்திற்கு ஆயிரக்கணக்கான முறை மிக அதிக இயற்பியல் அழுத்தத்திற்கு உட்படும் கருவியாகவும் கருதுங்கள். இதன் ஆயுட்காலம் பின்வருமாறு நிர்ணயிக்கப்படும்:

1.டை வடிவமைப்பு & கட்டுமானம்:

சிக்கல்தன்மை: எளிய பொந்து செய்யும் குறைகளில் வெற்று சிப்புகள் பொதுவாக ஒரு தாக்கத்தில் பல சிக்கலான அம்சங்களைக் கொண்ட தொடர் குறை வடிவங்களை விட மிகவும் நீண்ட கால ஆயுளைக் கொண்டிருக்கும். மிகவும் சிக்கலானதாக இருந்தால், அது அழிந்து போகலாம் மற்றும் அழுத்த குவியம் இருக்கக்கூடிய இடங்களில் இருக்கலாம்.

பொருள்: அடிப்படை என்பது கருவி எஃகின் தரம் மற்றும் கடினத்தன்மை (எ.கா. D2, A2, கார்பைடு செருகுதல்கள்). ஒரு குறிப்பிட்ட பொறுப்பிற்குள் கடினப்படுத்தப்பட்ட உயர்ந்த தர எஃகுகள், மென்மையான/குறைவாக கடினப்படுத்தப்பட்ட தர எஃகுகளை விட அதிக அளவில் அழிவு மற்றும் தாக்கத்தை தாங்கக்கூடியவை.

தாங்கக்கூடியத் தன்மை: போதுமான ஆதரவு, இடைவெளிகள், அழிவு பிளேட்டுகள் மற்றும் பூச்சுகளை (எ.கா. TiN, TiCN, CrN) பொதுவான தேர்வு மற்றும் முக்கியமான பாகங்களில் பயனுள்ள வழிநடத்தும் இயந்திரங்கள் ஆகியவை அழுத்தங்கள் மற்றும் அழிவில் முக்கிய பங்களிப்பை வழங்குகின்றன.

2.செயல்பாட்டு காரணிகள்:

அச்சு நிலைமைகள்: சரியான சீரமைப்பு, மிகையான விலகல், தவறான ஷட் உயரம் அல்லது நிலையற்ற அச்சு ஆகியவை குறைகளுக்கு அதிகபட்ச சேதம் விளைவிக்கும் ஆற்றலை வழங்குகின்றன, இது அழிவு மற்றும் உடைவுக்கு முக்கியமான பங்களிப்பை வழங்குகின்றன.

நிமிடத்திற்கு ஸ்டோக்ஸ் (SPM): வேகமான வேகம் குறைவான நேரத்தில் மேலும் வெப்பம் மற்றும் தாக்க சுழற்சிகளை உருவாக்குகிறது, இது உராய்வு மற்றும் சோர்வு போன்ற அணிவிக்கும் செயல்முறைகளை அதிகரிக்கிறது.

சீரற்ற செயல்முறை: இது செயலில் உள்ள செதிலின் உயிர்நாடி ஆகும், மேலும் சரியான சீரற்ற செயல்முறை பயன்படுத்தப்பட வேண்டும், மேலும் செதிலுக்கு சீரான செயலில் பாய்ச்சம் இருக்க வேண்டும். இது உராய்வை குறைக்கிறது, குளிர்விக்கிறது, காலிங் ஐ நீக்குகிறது மற்றும் குப்பையை வெளியேற்றுகிறது. மோசமான அல்லது தவறான சீரற்ற செயல்முறை ஆரம்ப செதில் கண்டறிதலின் மிகவும் முக்கியமான பிரச்சினையாகும்.

டன்னேஜ்: அதிகபட்ச விகிதத்திற்கு நெருக்கமாக அல்லது அதற்கு மேல் உற்பத்தி செய்வது செதிலை மிகவும் விரைவாக அழிக்கிறது, ஏனெனில் இது ஓவர்லோடு செய்யப்படுகிறது.

3.அச்சிடப்படும் பொருள்:

வலிமை மற்றும் கடினத்தன்மை: உயர் வலிமை கொண்ட எஃகுகள் (HSS), மேம்பட்ட உயர் வலிமை கொண்ட எஃகுகள் (AHSS) அல்லது கடினப்படுத்தப்பட்ட பொருள்களை அச்சிடுவது அலுமினியம் அல்லது மெதுவான எஃகு போன்ற இலகுரக மென்மையான உலோகங்களை அச்சிடுவதற்கு ஒப்பிடும்போது செதிலின் பரப்புகளில் மிகவும் அதிகமான செதில் அழிவை உருவாக்குகிறது.

உராய்தல்: உராய்தல் தன்மை கொண்ட பொருட்கள் (எ.கா. சூடான-ரோல் செய்யப்பட்ட எஃகு) அல்லது கடினமான துகள்களைக் கொண்டுள்ள பொருட்கள் வெட்டும் ஓரங்களையும், வடிவாக்கும் பரப்புகளையும் விரைவாக மங்கலாக்கும் தன்மை கொண்டவை.

தடிமன்: அதிக தடிமன் கொண்ட பொருட்கள் அதிக டன் திறனை தேவைப்படுத்தும், இது டை (die) அமைப்பின் மீது அதிக வலிமையை சுமத்தும்.

4. பராமரிப்பு மற்றும் கையாளுதல்:

தடுப்பு பராமரிப்பு (PM): தடுப்பு பராமரிப்பில் சரியான சுத்தம் செய்தல், பார்வையிடுதல், வெட்டும் பகுதிகளையும், வெட்டி எடுக்கும் பகுதிகளையும் கூர்மையாக்குதல், அழிப்பு பாகங்களை மாற்றுதல் (பேடுகள், சுருள்கள், வழிகாட்டும் குச்சிகள்) மற்றும் அதிகபட்ச டை (die) ஆயுளை பெறுவதற்காக பொதுவான பராமரிப்பு பூக்குதல் ஆகியவை அடங்கும். PM இல்லாமல் இருப்பதன் மூலம் சிறிய பிரச்சினைகள் பெரிய பேரழிவுகளாக மாறும்.

சேமிப்பு மற்றும் கையாளுதல்: பாதுகாப்பாக சேமிக்கவும், கையாளும் போது துருப்பிடித்தல், கீறல், குழிப்பாடு அல்லது கூட கீழே விழுதலை தவிர்க்கவும் பொருட்களை சரியான முறையில் கையாள வேண்டும். பொருட்கள் பாதிக்கப்பட்டால் மாற்றும் செயல்முறை அல்லது கொண்டு செல்லும் செலவு மிகவும் அதிகமாக இருக்கும்.

தோல்வி முறைகள் "ஆயுள் முடிவு" ஐ தீர்மானிக்கின்றன:

ஒரு டை (die) முழுமையாக வேலை செய்வதை நிறுத்தும் போது அதன் ஆயுட்காலம் முடிவடைவதில்லை; பராமரிப்புச் செலவு மிகவும் அதிகமாக இருக்கும் போது அல்லது பாகங்களின் தரம் அழிந்து போகும் போது, பல நேரங்களில் அது பொருளாதார ரீதியாக பழுதடைந்து விடுகிறது. சாதாரணமான தோல்விகளின் வகைகள்:

அரிப்பு (Wear): வெட்டும் விளிம்புகள் மற்றும் வடிவமைக்கும் பரப்புகளில் காணத்தக்க அரிப்பு, பொந்துகள், அளவில் துல்லியமின்மை, அல்லது பாகத்தின் மேற்பரப்பு சரியில்லாமை ஆகியவற்றிற்கு காரணமாகிறது.

சோர்வு விரிசல் (Fatigue Cracking): அழுத்த சுழற்சிகளால் சோர்வு உருவாகி, விரிசல்களை உருவாக்குகிறது, இது நேரம் செல்லும் வளர்ந்து, பகுதிகள் உடைந்து போக காரணமாகிறது.

பிளாஸ்டிக் விரூபமடைதல் (Plastic Deformation): மென்மையான புள்ளிகள் அல்லது மிகைச் சுமையால் டை ஸ்டீலின் (die steel) விரூபமடைதல் நிரந்தரமானது.

மென்மையான துகள்கள் உதிர்தல் (Brittle Chipping): தோல்வியின் மென்மையான முறை, சாதாரணமாக கூர்மையான விளிம்புகள் அல்லது கூர்மையான மூலைகளில் ஏற்படுகிறது.

உருக்குலைவு (Galling): டை மற்றும் பணிப்பொருளுக்கு இடையே பொருள்களின் பரிமாற்றம் மற்றும் ஒட்டுதல் ஆகும், இது மோசமான மேற்பரப்பு சேதத்திற்கு வழிவகுக்கிறது.

நிலைமையான எதிர்பார்ப்புகள் மற்றும் ROI கண்ணோட்டம்:

⦁ பின்வருவனவற்றின் சாதாரண வரம்புகள் என்ன? மேலே குறிப்பிட்ட காரணிகளின் தாக்கத்திற்கு இது பெரும்பாலும் உட்பட்டது:

சாதகமான சூழ்நிலைகளில் எளிய, அதிக அளவு பிளாங்கிங் செய்யும் டைகள் பெரிய அளவில் பழுது பார்க்கும் வரை 1 மில்லியன் அல்லது அதற்கு மேல் செயல்படலாம்.

கடினமான பொருட்களை (கடினமான பொருட்களை ஸ்டாம்பிங் செய்வது) ஸ்டாம்ப் செய்யும் சிக்கலான புரோகிரஸிவ் டைகள் பெரும் பழுது பார்க்கும் இடைவெளிக்கு இடையில் 100,000 முதல் 500,000 சுழற்சிகள் வரை நீடிக்கலாம்.

மிகவும் தேய்க்கக்கூடிய அல்லது மிக அதிக வலிமை கொண்ட பொருட்களை உருவாக்கும் டைகள் பழுது பார்க்கும் முன் வெறும் 50,000 சுழற்சிகள் அல்லது அதற்கும் குறைவாகவே நீடிக்கலாம்.

உங்கள் முதலீட்டை அதிகபட்சமாக்குதல்:

கிடைக்கக்கூடிய வாழ்நாளில் இருந்து அதிகபட்சம் பெறுவதற்கு பதிலாக, கிடைக்க முடியாத அளவு ஆண்டுகளை மையமாக கொள்ள வேண்டாம்:

1.தரத்தில் முதலீடு: தரத்தில் முதலீடு செய்யுங்கள்; அதாவது, தரமான வடிவமைப்பு மற்றும் தரமான பொருட்கள்/கட்டுமானத்தில் முதலீடு செய்யுங்கள்.

2.செயல்முறையை எளிமைப்படுத்துதல்: பிரஸின் ஆரோக்கியத்தை, சரியான அமைவுகளை மற்றும் சிறந்த சூழலை பராமரிக்கவும்.

3.கண்டிப்பான தடுப்பு பராமரிப்பு: தடுப்பு பராமரிப்பு போதகம் மற்றும் பயிற்சி முறையாக இருக்க வேண்டும்.

4.பயிற்சி பெறும் பணியாளர்கள்: டைகளை கையாள்வது, அமைப்பது மற்றும் இயங்கச் செய்வது மிகவும் முக்கியமானது.

5.பாகத்தின் தரத்தைக் கண்காணிக்கவும்: பராமரிப்பை முன்கூட்டியே கணிப்பதற்காக பர்ர் அளவு அல்லது அளவுரு செயலில்லாமை போன்ற அணிகலன்களைக் கண்காணிக்கவும்.

கூடுதல்:

உலோக ஸ்டாம்பிங் செய்யும் குறிப்பிட்ட ஆயுட்காலம் முன்கூட்டியே முடிவு செய்ய முடியாதது. அதன் அமைப்பு, கட்டுமானம், பயன்பாடு மற்றும் பராமரிப்பில் எடுக்கப்பட்ட முடிவுகளை அடிப்படையாகக் கொண்டு இது நேரடியாக உருவாகின்றது. அழிவு மற்றும் தோல்வியை நிர்ணயிக்கும் காரணிகளைக் கற்று அதனை பயனுள்ள முறையில் முக்கியத்துவம் கொடுப்பதன் மூலம், தயாரிப்பு ஆயுளை அதிகரிக்க முடியும், இதனால் குறைந்த செலவில் தரமான பாகங்களை உற்பத்தி செய்ய முடியும் மற்றும் இந்த முதலீட்டின் மீதான வருமானம் அதிகரிக்கப்படும். இதன் முக்கிய நோக்கம் அழிவில்லாமை அல்லது வாய்ப்பு சார்ந்த நீடித்த ஆயுளை விட, செயல்முறை ஒழுங்குமுறை மற்றும் பராமரிப்பில் கடின உழைப்பின் மூலம் சிறப்பாக்கப்பட்ட கணிசமான ஆயுளை நோக்கி செல்வதாகும்.