In the exciting universe of things getting made, a special tool called a "progressive tool" is revolutionizing the way products are manufactured. Lihao is a company whose products we have the honor to introduce here and who can apply this cool water transfer technology to high-quality products most well.

Tool and die making is one of those trades that’s been around a long time and has helped to produce a lot of goods such as automobiles and household products. Historically, making a tool and die was a matter of making individual parts and assembling them. But now, with new technology, progressive tool die somehow is a better and cheaper way to do it.

“The timing,” John says, “‘is like a ballet.'” Progressive tool die is a process in which one tool performs several operations on a single part in sequence. This is a big deal because it saves countless minutes of your life by allowing you to do everything at once, in one tool, instead of having to use many different tools to do multiple steps. This saves time and avoids waste, which reduces costs.

Progressive tool die has so many pluses in manufacturing. There are some huge benefits to the speed at which parts can be produced. Production times are far shorter when everything can be done at once. Products can thus be manufactured faster, enabling companies to respond more quickly to customer demand.

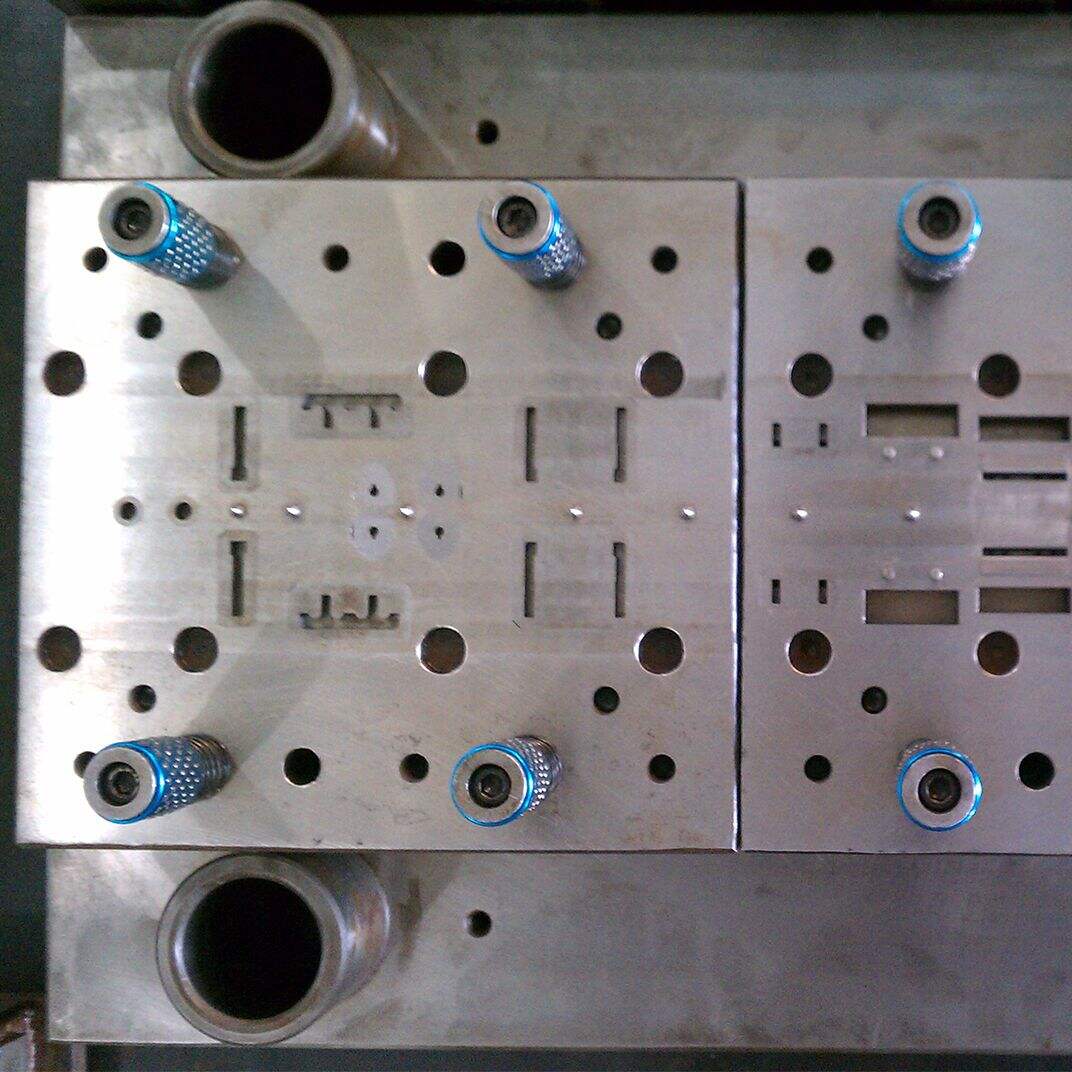

When the tool is finished, it is inserted into a press machine and the process begins by means of a progressive stamping. The machine forces the material, the material takes the shape of your tool. As the material travels through the machine, it passes through various stages until the final part is complete.

The progressive tool die is revolutionizing the manufacturing world on a number of fronts. One of the main advantages is that you will be saving money in this way. With so many tasks done with one tool, the companies are able to use fewer tools and spend less time and labor making parts. That leads to lower costs — and more profit — for companies like Lihao.

Companies can be more efficient and produce higher quality items when they use progressive tool and die. The faster the smoother process, the faster the production time, which helps a company better meet their customer’s needs. Excellent cuted and constant parts are produced with progressive tool die for high quality products.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our progressive tool die offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

And over 26 years experience in industry leadership, Lihao Machine is a supplier which was top the domestic and international markets. Our products is widely found in a wide range of. All over the world with nearly 20 offices across China because well as an overseas subsidiary India we provide our clients. We provide customized solutions in several industries, with your robust technological abilities.

Lihao Machine provides tailored solutions also as a complete service meet up with the various needs of customers. You can expect integrated solutions which cover design, production and sales. Our R&committed D team provide you with customized choices and technical discussions making sure each option would be suited to your unique criteria.

Our dedication to reliability, innovation and continual improvement of services and products is an ongoing process. Our Lihao team is highly skilled and offers options cutting-being edge. Our company is the first selection automation of. We spot a high priority ensuring customer care by consistently delivering the very best solutions and services.