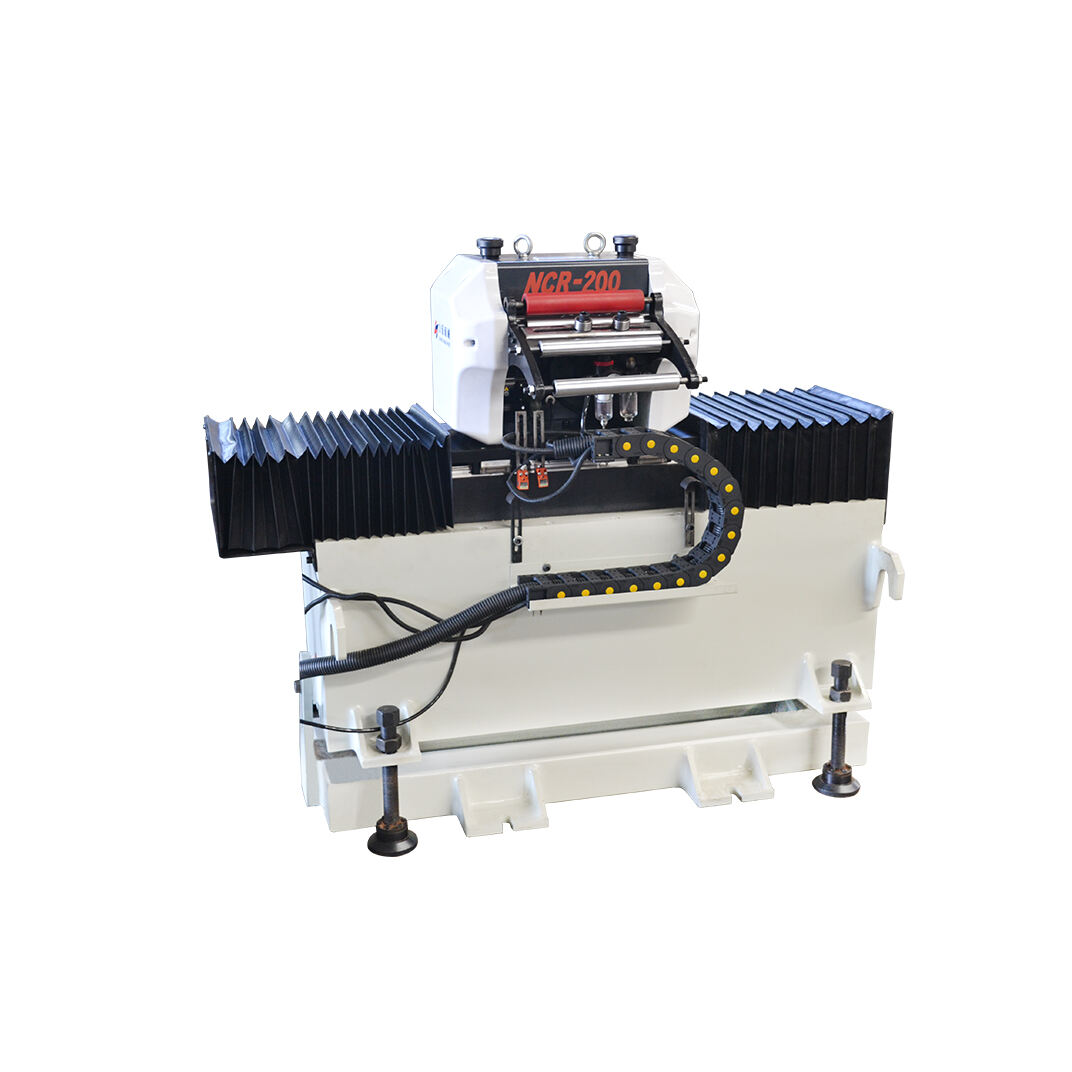

Have you ever looked at those great big machines that make metal parts? To run better, these machines require something known as a nc servo roll feeder. Basically, a servo roll feed is a robotic helper that assists in gripping and pulling the metal sheets into the machine so they can be cut or shaped. It just makes everything faster, and smoother.

When you create metal parts, they need to be the correct size and shape. This is where servo roll feed systems come into play. They help ensure the metal sheets go into the machine properly. What this means is your pieces will come out exactly the way you want them, every time.

Metal forming is the shaping of metal: You start with a flat sheet, a piece of solid metal, and you turn it into a three-dimensional shape—say a car part or a household appliance. Servo roll feed technology can do this better. It helps ensure the metal sheet is fed into the machine at the appropriate speed and angle so the final material is ready to use.

There’s nothing more critical when creating metal parts than feeding the metal sheet into the machine the same way every time. This is an area where servo roll feed equipment can be of assistance. It ensures a consistent delivery of the metal sheet in, so your parts come out right every time, no matter how many you make.

"When you press on it, that's press operation, where you are using a machine to press down on a piece of metal to form it. You will find that a servo roll feed solution can greatly help with this process and make it go much smoother. They aid in feeding the metal sheet into the machine at precise speed, and at the exact angle so that the press can perfectly perform its task every time.