Having Difficulty Loading Metal Sheets into Your Stamping Press Manually? If yes, then Lihao has a wonderful way deal for you! This is what our automated die stamping presss are designed to help with. That is why these coolest automation machines feed metal sheets to your stamping press in a fast and seamless manner. This saves time and eliminates the need of requiring somebody from your team to sit down and spend hours dusting off the heavy lifting yourself.

Our stamping press feeders allows you to produce more products than ever before. Metal sheets into the press are continuous as they carry them through. So you will not have to stop what you are doing to insert the sheets yourself. You can concentrate on other more valuable tasks that require your focus while the metal sheets are being fed in perfectly and timely.

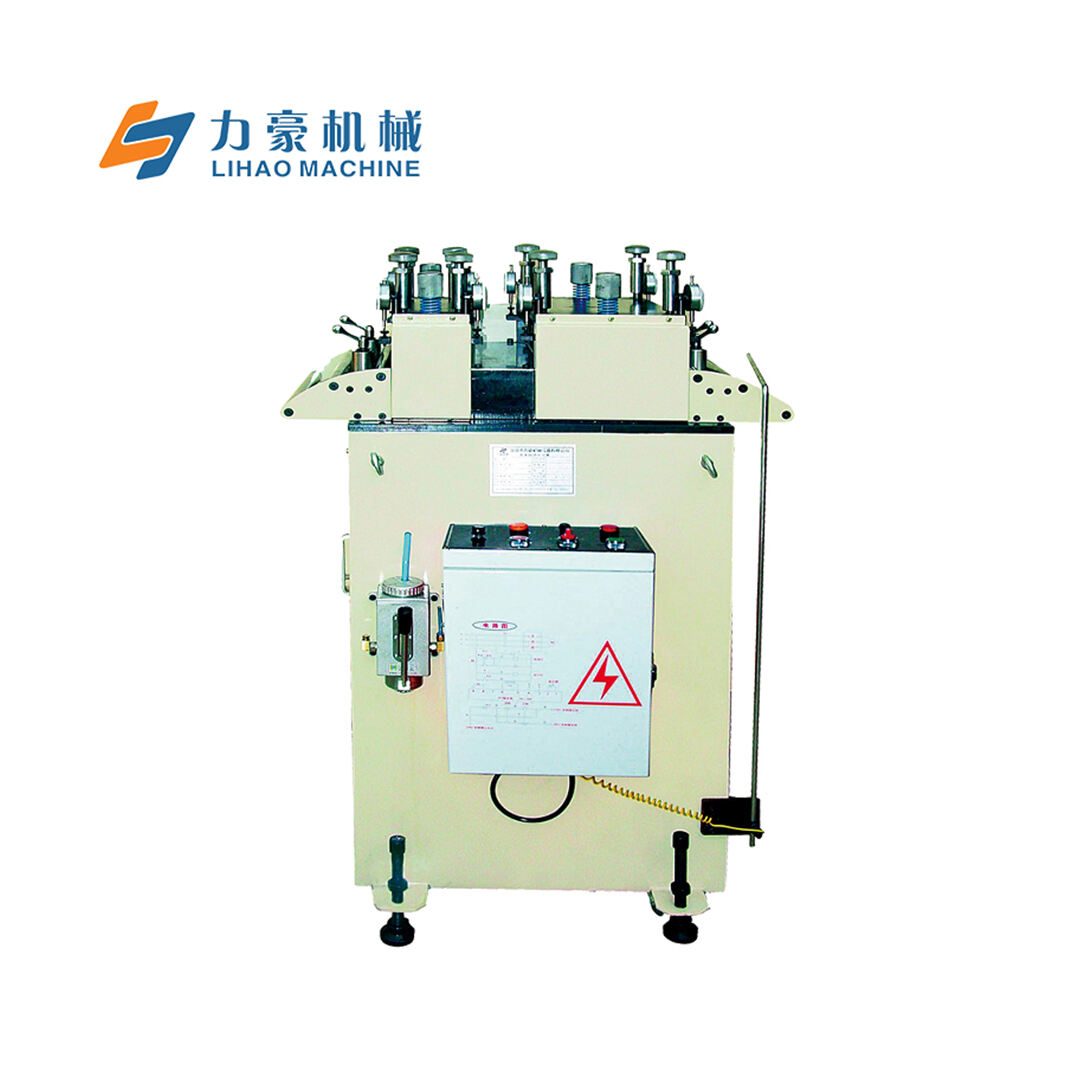

The metal stamping presss from Lihao are made with very high precision and reliability. A lot of precautions are done while making our machines to make sure each metal sheet goes in the press properly. And this precision is crucial as it reduces errors and wastage, which in turn increases output and lowers costs.

Every production line is unique, and Lihao recognized this very well. This is the key reason behind our custompress feeding arrangements that can be modified specifically for your need. We want to know what is your need and ensure that our technicians will work with you where it fits into your workflow as a feeder.

Employing customized feeders can significantly enhance the functionality of your production line. They help things run more smoothly and save time. When the feeder is built to you, it will be perfectly integrated with your other machines and processes which enables a more effective production line.

Any production environment knows that mistakes and waste are very costly when it comes to money. The stamping press feeders from Lihao is a very crucial equipment that assists inconveniences associated with these kinds of errors. It helps to feed metal sheets in the press with precision, accurately and reliably. Our machines ensure that each sheet will be fed properly thus reducing errors and the waste.

The feeders we use for our making process are of latest technology, which means that every metal sheet is given accuracy and care when it comes to feeding. These precision helps you to reduce mistakes and wastage; resulting in better quality products, and your customers are much happier and satisfied.

We excel in the area of engineering and durable tooling designs, minimizing adjustments to your setup plus thus reducing production which is scrap. Our stamping press feeder offer worldwide commissioning and training that ensures integration that is seamless maximised performance across the earth. With in-house manufacturing and quality spare parts support We ensure minimum interruptions while the productivity that are highest. We have been ISO9001 certified and CE which is EU certified.

Lihao Machine offers tailored solutions along with a wide range of services to fulfill various customer. With a broad variety of merchandise, including 3 within one feeders, Decoiler Cum Straightener machines, NC servo feeders, and punch machines, you can expect integrated service covering manufacturing design, sales, service, and trading. Our R&D team is dedicated to ensuring customization and technical discussions, ensuring that each product was designed to hook up together with your unique specifications.

Lihao Machine happens to be the marketplace leader for 26 ages. It's the trusted provider both domestic and international markets. Our items are extensively utilized in many industries throughout the world. We offer our customers throughout the global world with nearly 20 offices in China and an indian branch. We offer tailored systems around many industries using our advanced technological capabilities.

Our dedication to quality, reliability and continual improvement of products and service is an ongoing procedure. Our Lihao team is highly skilled and offers cutting-edge solutions. We are the true number one solution in stamping automation. We place great importance in ensuring consumer satisfaction by consistently supplying the quality highest products plus services.