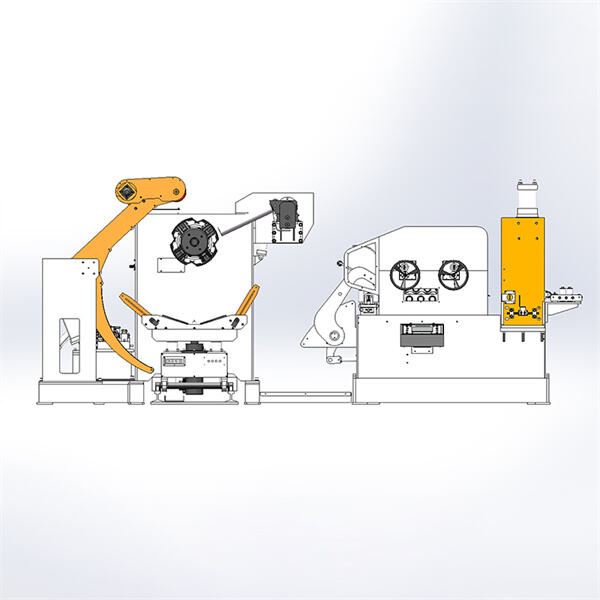

Sheet metal feeders … Design Description: Sheet metal feeders are devices used in the production of sheet metal products. These machines are employed in factories to ease and speed work. how sheet metal feeders work and why they're important to making things!

Sheet metal feeders are devices that take sheet metal into other machines to fabricate. They are employed in the likes of cars, airplanes, and building construction. Sheet metal feeders can vary in size and shape to match the variety of sheet metal and what is required of production.

The main point in favor of sheet metal decoilers is that production becomes better. Feeding the sheet metal can be automated, so workers can do other things. Which speeds up the work and helps prevent mistakes. It saves time and reduces errors throughout production.

There are plenty of great things about sheet metal feeder in the factory. An important benefit is helping to avoid waste. By properly feeding the sheet metal into machines, sheet metal feeders can ensure that the most is made of the materials and that there is less waste.

Another advantage is that the sheet metal feeders could help improve the quality of the products. These machines enable the production of goods that conform to the required standards by offering a reliable and precise feeding of the material from the sheet metal.

Sheet metal feeders are designed to consistently and accurately make production. This type of feeder is ideal for feeding sheet metal into machines just the right way so that the feed is consistent and cow powders are processed in a uniform manner. That’s particularly important in industries where a small mistake can lead to big problems.

A sheet metal feeder in a factory can increase productivity. With automatic feeding, that frees the employees up for other work, so you get more done. Sheet metal feeders also serve to speed up the process The shorter the time to make a product, the faster the result and the more items produced.